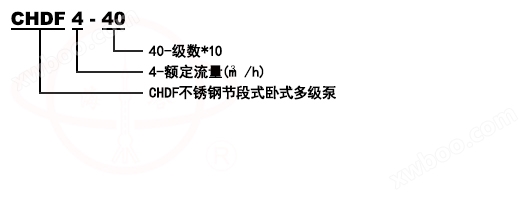

Model Meaning

Product Introduction

CHDF stainless steel segmental horizontal multi-stage pump with horizontal extended shaft motor, axial suction, radial discharge. The overcurrent components of the pump are all made of high-quality stainless steel plates stamped and welded, making the pump also suitable for mildly corrosive media. The product adopts excellent hydraulic models and advanced manufacturing processes, with characteristics such as wide applicability, high efficiency and energy saving, and reliable quality.

Application scope

CHDF stainless steel segmental horizontal multi-stage pump is suitable for industrial and domestic water use.

● Air conditioning system

Fertilization and metering system

● Cooling system

● Environmental applications

● Industrial cleaning

● Water supply or pressurization system

● Water treatment (purification of water)

● Domestic water supply

● Aquaculture

● (Other) Many specialized and specific purposes

condition

Liquid temperature: Room temperature type: -15 ℃~+70 ℃ Hot water type:+70 ℃~+110 ℃

● Environmental temperature:+40 ℃

Operating pressure: 10 bar

The high import pressure is limited by operational pressure.

● Transport medium

A non flammable and explosive liquid that is thin, clean, and free of solid particles or fibers.

Pumps can transport light chemical media such as mineral water, softened water, pure water, clean oil, and others.

When the density or viscosity of the conveyed liquid is greater than that of water, a high-power motor must be used if necessary.

Whether a pump is suitable for a specific liquid is determined by multiple factors, including chlorine content, pH value, temperature, solvent, oil content, etc.

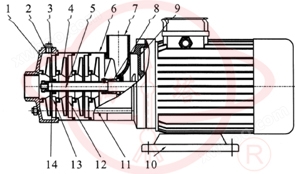

Structure diagram

|

Serial Number |

name |

material |

AISI/ASTM |

Serial Number |

name |

material |

AISI/ASTM |

1 |

Entering the water body |

stainless steel |

AISI304 |

8 |

mechanical seal |

|||

2 |

plug |

stainless steel |

AISI304 |

9 |

Motor end cover |

aluminum alloy |

||

3 |

bearing |

tungsten carbide |

10 |

base |

cast iron |

ASTM258 |

||

4 |

impeller |

stainless steel |

AISI304 |

11 |

pull rod |

stainless steel |

AISI304 |

|

5 |

axle |

stainless steel |

AISI304 |

12 |

Guide vane |

stainless steel |

AISI304 |

|

6 |

Water outlet guide vane |

stainless steel |

AISI304 |

13 |

Supporting guide vanes |

stainless steel |

AISI304 |

|

7 |

Water outlet |

stainless steel |

AISI304 |

14 |

Impeller spacer |

stainless steel |

AISI304 |

performance parameter

model |

Motor N (KW) |

Flow rate Q (m3/h) |

0.5 |

1.0 |

1.5 |

2.0 |

2.5 |

3.0 |

3.5 |

CHDF2-20 |

0.37 |

Head H (m) |

19 |

18 |

16 |

14 |

13 |

11 |

9 |

CHDF2-30 |

0.55 |

Head H (m) |

28 |

27 |

24 |

21 |

20 |

17 |

14 |

CHDF2-40 |

0.55 |

Head H (m) |

36 |

34 |

32 |

28 |

26 |

23 |

17 |

CHDF2-50 |

0.55 |

Head H (m) |

46 |

43 |

40 |

35 |

33 |

28 |

22 |

CHDF2-60 |

0.75 |

Head H (m) |

54 |

50 |

48 |

42 |

38 |

33 |

25 |

|

|

|||||||||

model |

Motor N (KW) |

Flow rate Q (m3/h) |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

CHDF4-20 |

0.55 |

Head H (m) |

19 |

18 |

16 |

15 |

13 |

10 |

7 |

CHDF4-30 |

0.55 |

Head H (m) |

28 |

27 |

24 |

22 |

19 |

15 |

10 |

CHDF4-40 |

0.75 |

Head H (m) |

38 |

36 |

32 |

30 |

26 |

20 |

14 |

CHDF4-50 |

1.1 |

Head H (m) |

46 |

44 |

41 |

38 |

32 |

26 |

20 |

CHDF4-60 |

1.1 |

Head H (m) |

55 |

53 |

50 |

45 |

37 |

31 |

26 |

|

|

|||||||||

model |

Motor N (KW) |

Flow rate Q (m3/h) |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

CHDF8-10 |

0.75 |

Head H (m) |

9.5 |

9.3 |

9 |

8.5 |

7.5 |

6.5 |

5.5 |

CHDF8-20 |

0.75 |

Head H (m) |

19 |

18.5 |

18 |

17 |

15 |

13 |

11 |

CHDF8-30 |

1.1 |

Head H (m) |

29 |

28 |

27 |

25.5 |

22.5 |

20 |

17.5 |

CHDF8-40 |

1.5 |

Head H (m) |

39 |

38 |

36 |

34 |

30 |

26.5 |

22.5 |

CHDF8-50 |

2.2 |

Head H (m) |

49 |

47 |

45 |

42.5 |

38 |

33.5 |

28 |

|

|

|||||||||

model |

Motor N (KW) |

Flow rate Q (m3/h) |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

CHDF16-10 |

1.1 |

Head H (m) |

12 |

11.5 |

10.5 |

10 |

9 |

7.5 |

6.5 |

CHDF16-20 |

2.2 |

Head H (m) |

24 |

23 |

22 |

21 |

19 |

17 |

14.5 |

CHDF16-30 |

3 |

Head H (m) |

37 |

36 |

34 |

32 |

30 |

27 |

23 |

CHDF16-40 |

4 |

Head H (m) |

50.5 |

49 |

46 |

43 |

40.5 |

36 |

31.5 |

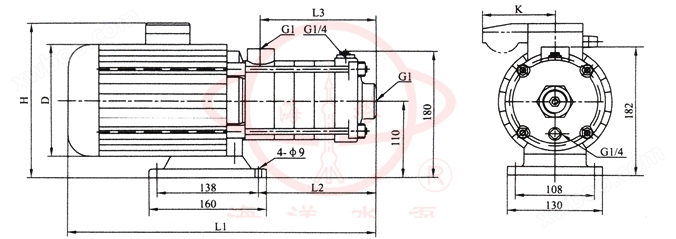

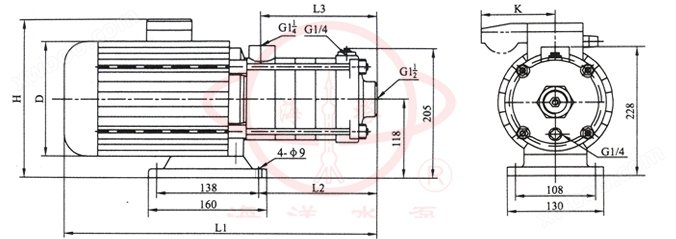

Installation size

|

||||||||

model |

electrical machinery |

L1(mm) |

L2(mm) |

L3(mm) |

D(mm) |

H(mm) |

K(mm) |

Weight (kg) |

CHDF2-20 |

single phase |

305 |

87 |

84 |

145 |

215/230 |

/96 |

15 |

CHDF2-30 |

single phase |

323 |

105 |

102 |

145 |

215/230 |

/96 |

15 |

CHDF2-40 |

single phase |

341 |

123 |

120 |

145 |

215/230 |

/96 |

15 |

CHDF2-50 |

single phase |

359 |

141 |

138 |

145 |

215/230 |

/96 |

15 |

CHDF2-60 |

single phase |

422 |

159 |

156 |

170 |

225/245 |

/100 |

17 |

|

||||||||

model |

electrical machinery |

L1(mm) |

L2(mm) |

L3(mm) |

D(mm) |

H(mm) |

K(mm) |

Weight (kg) |

CHDF4-20 |

single phase |

329 |

105 |

102 |

145 |

215/230 |

/96 |

15 |

CHDF4-30 |

single phase |

356 |

132 |

129 |

145 |

215/230 |

/96 |

15 |

CHDF4-40 |

single phase |

416 |

162 |

156 |

170 |

225/245 |

/100 |

17 |

CHDF4-50 |

single phase |

455 |

188 |

183 |

170 |

225/245 |

/100 |

17 |

CHDF4-60 |

single phase |

482 |

213 |

210 |

170 |

225/245 |

/100 |

17 |

|

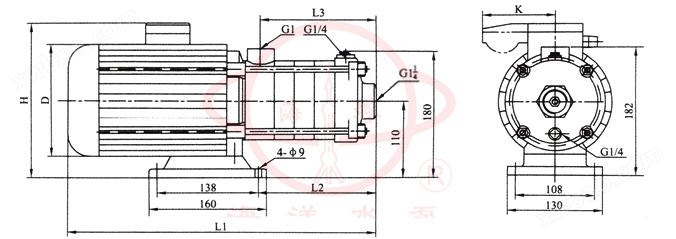

||||||||

model |

electrical machinery |

L1(mm) |

L2(mm) |

L3(mm) |

D(mm) |

H(mm) |

K(mm) |

Weight (kg) |

CHDF8-10 |

single phase |

395 |

126 |

108 |

170 |

230/252 |

/100 |

20 |

CHDF8-20 |

single phase |

395 |

126 |

108 |

170 |

230/252 |

/100 |

20 |

CHDF8-30 |

single phase |

425 |

156 |

138 |

170 |

230/252 |

/100 |

25 |

CHDF8-40 |

single phase |

490 |

186 |

168 |

180 |

240/260 |

/100 |

28 |

CHDF8-50 |

single phase |

520 |

216 |

198 |

180 |

240/260 |

/100 |

30 |

|

|||||||||||||||

model |

electrical machinery |

L1 |

L2 |

L3 |

H |

D |

E |

N |

A |

M |

B |

j |

d |

k |

Weight (kg) |

CHDF16-10 |

single phase |

423 |

151 |

126 |

230/265 |

180 |

227 |

117 |

130 |

108 |

160 |

138 |

9 |

/100 |

17.5 |

CHDF16-20 |

single phase |

455 |

151 |

126 |

240/270 |

180 |

228 |

118 |

130 |

108 |

160 |

138 |

9 |

/100 |

27 |

CHDF16-30 |

single phase |

561 |

196 |

171 |

270/ |

195 |

240 |

130 |

130 |

108 |

160 |

138 |

9 |

33 |

|

CHDF16-40 |

single phase |

621 |

339 |

216 |

270/ |

220 |

230 |

120 |

230 |

109 |

190 |

140 |

12 |

41 |

|

Repair and maintenance

Maintenance and upkeep during operation

1. The inlet pipeline must be highly sealed and must not leak or leak.

2. Do not operate the pump for a long time under cavitation conditions.

3. Prohibit the pump from operating at high flow rates and the motor from running at overcurrent for extended periods of time.

4. Regularly check the motor current value during pump operation to ensure that the pump operates within the design operating range as much as possible;

5. The pump should be supervised by a dedicated person during operation to prevent accidents.

6. Oil should be added to the bearings every 500 hours of pump operation.

7. After long-term operation of the pump, if the noise and vibration of the unit increase due to mechanical wear, it should be stopped for inspection. If necessary, vulnerable parts and bearings can be replaced. The overhaul period of the unit is generally one year. Mechanical seal maintenance and upkeep

1. Mechanical seal lubrication should be clean and free of solid particles.

2. It is strictly prohibited for mechanical seals to work under dry grinding and idling conditions.

3. Before starting, the pump (motor) should be turned a few times to avoid sudden starting causing damage to the sealing ring.

Fault causes and troubleshooting methods

Fault phenomenon |

Possible causes |

Troubleshooting |

1. The water pump is not producing water |

a、 The import and export valves are not open, the inlet and outlet pipelines are blocked, and the impeller of the flow channel is blocked. b、 The motor is running in the wrong direction and has a slow speed due to phase loss. c、 The suction pipe is leaking air. d、 The pump is not filled with liquid and there is air inside the pump chamber. e、 Insufficient imported water supply, high suction, and leaking bottom valve. f、 Excessive pipeline resistance and improper pump selection. |

a、 Check and remove blockages b、 Adjust the motor direction and strengthen the motor wiring c、 Tighten all sealing surfaces and eliminate air d、 Open the pump cover or open the exhaust valve to exhaust the air e、 Shutdown inspection and adjustment (this phenomenon is prone to occur when using grid connected water pipes and suction pumps) f、 Reduce pipeline bends and reselect pumps. |

2. Insufficient water pump flow |

a、 First, check the cause according to 1. b、 Pipeline, pump, impeller flow channel partially blocked, scale deposition, insufficient valve opening c、 Low voltage d、 Impeller wear |

a、 First, press 1. Exclude b、 Remove the obstruction and readjust the valve opening. c、 Stabilize voltage. d、 Replace the impeller. |

3. Excessive power |

a、 Exceeding the rated flow usage b、 High suction distance c、 Pump shaft wear |

a、 Adjust the flow rate and turn down the outlet valve b、 reduce c、 Replace bearings |

4. Noise vibration |

a、 The pipeline support is unstable. b、 Liquid mixed with gas. c、 Generate cavitation. d、 The bearing is damaged. e、 The motor is running under overload and overheating. |

a、 Stable pipeline b、 Increase import pressure and exhaust c、 Reduce the vacuum degree d、 Replace bearings e、 Adjust according to 4. |

5. Motor overheating |

a、 Excessive traffic and overloaded operation. b、 Rubbing. c、 The motor bearings are damaged. d、 Insufficient voltage. |

a、 Close the outlet valve. b、 Check and eliminate. c、 Replace the bearings. d、 Stabilize voltage. |

6. Water pump leakage |

a、 Mechanical seal wear. b、 The pump body has sand holes or fractures. c、 The sealing surface is uneven. d、 Loosen the installation bolts. |

a、 Replace. b、 Welding repair or replacement. c、 Repair. d、 Durable. |